Photoelectric Sensors

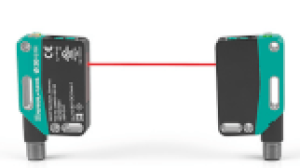

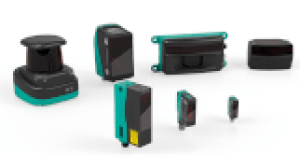

The emitter and receiver on thru-beam sensors are aligned opposite one another. The advantage of this is that the light reaches the receiver directly and long detection ranges and high excess gain can therefore be achieved. These sensors are capable of reliably detecting almost any object. The angle of incidence, surface characteristics, color of the object, etc., are irrelevant and do not influence the functional reliability of the sensor.

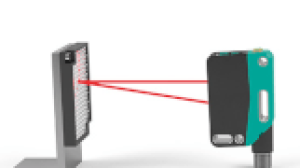

The emitter and receiver are aligned in a housing such that the retroreflective sensors are easy to install. Simply position a reflector on the opposite side and align the sensor with it. The standard version featuring a polarization filter combines the installation benefits offered by the retroreflective system with the reliable detection, even of reflective objects, at long detection ranges. The retroreflective sensors for clear object detection are ideal for reliably detecting transparent objects.

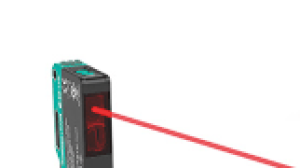

Diffuse mode sensors are particularly easy to install, since only one device has to be fitted and no reflector is required. These sensors operate primarily at close range, feature optimum switching accuracy, and can reliably detect even very small objects. The sensors with background suppression sense only a specific area in front of the sensor. The sensor ignores any objects that are outside of this area. Sensors with background suppression are also insensitive to interfering objects in the background and are still extremely precise. Sensors with background evaluation are always used in applications with a fixed background in the measuring range with which you can align the sensor.

Switching sensors with measurement core technology are based the Multi Pixel Technology (MPT) developed by Pepperl+Fuchs. Thus, multiple operating modes and switching points are easily set up in a single triangulation sensor. These photoelectric sensors can be configured as background suppression sensors, background evaluation sensors, and in window operation mode. Additionally, the sensors are equipped with a standard IO-Link interface which enables users to easily integrate them into versatile applications.

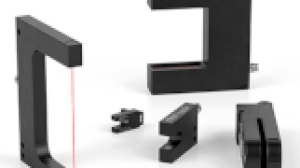

Fiber optic sensors and cables are the perfect solution for applications where the direct mounting of sensors is not possible due to space restrictions, temperature extremes, and so on. Small fiber optic beams are ideal for detecting tiny objects.

With a fast response time, the devices are ideal for detecting tiny objects from long distances. They are frequently used to detect objects on vibrating and oscillating conveyors. Slot grid sensors handle challenging counting and monitoring tasks such as detecting non-guided objects in free fall.

In the automation of packaging and printing processes, the reliable detection of print and color marks plays a key role in coordinating the various processing steps. Photoelectric contrast sensors are specially designed for such detection tasks.

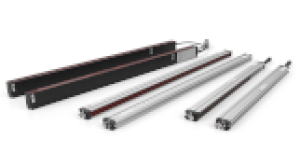

Light grids are ideal for applications where wider areas need to be monitored. Light grids are much easier to mount, install, and align and are therefore preferred to multiple individual photoelectric sensors. Application areas range from controlling the width, height, and profile of pallets in material handling facilities to detecting position-independent objects, controlling overlap on larger conveyed goods, and monitoring elevator doors.

Even the smallest model is suitable for a wide range of measuring and positioning tasks. It operates using laser triangulation and an analog output. All other sensors from the VDM series use Pulse Ranging Technology, offer long sensing ranges, and achieve extremely accurate measurement results. PRT uses high-intensity light pulses to provide a high degree of operating reliability, even under difficult ambient conditions with exposure to ambient light and dust.

The optical data couplers were designed to establish wireless communication with stock feeders, industrial trucks, automated transportation systems, overhead conveyors and docking stations. Mechanical and problematic RF- and Wi-Fi-based transmissions are avoided as a result. Devices with a variety of operating ranges and transfer rates are available.

Pepperl+Fuchs developed a number of industry-specific special devices for applications that are functionally not covered by the standard program. The application-specific sensors offer completely new possibilities in optical sensor technology for the user searching for the “right” solution.

Personnel protection is becoming increasingly important in automated processes. Wherever machines perform high-risk movements, the relevant health and safety regulations must be observed. Even if the operator is momentarily distracted, shearing, crushing, and impact injuries must be prevented.

Nowadays, it is hard to imagine life without escalators, automatic doors, gates, barriers, and elevators. As if by magic, they open automatically, detect obstacles, and appear to react quite naturally to approaching people and objects.

An extensive selection of accessories complements our photoelectric sensors product line, with application-specific fiber optic cables, mounting brackets, and a broad range of reflectors.